| US Coast Guard |

| Integrated Systems Management |

"We estimate that using Iron Speed Designer saved at least $1 million in project costs."

- Akesh Gupta, Co-founder of Light Speed Solutions

|

|

|

Integrated Systems Management |

US Coast Guard

New York, NY USA

|

The Integrated Systems Management (ISM) application was developed for the

US Coast Guard, whose primary contractor was ITT Corporation. Light Speed

Solutions worked as a sub-contractor for the design and development of ISM.

The US Coast Guard needed a system to document and track all actions for their

180 Response Boat Medium (RB-M) boats (www.responseboatproject.net).

Integrated Systems Management application was a new application that completely

integrated all functions required to track the entire lifecycle of a US Coast

Guard boat. The system tracks the components and any variances from the engineering

baseline during initial manufacturing through regularly scheduled maintenance

and other corrective actions, parts inventory, and ordering from various vendors.

The application also maintains all technical reference manuals required to maintain

and repair each boat. Prior to the ISM application, this entire process was performed

by disparate non-integrated systems.

The Integrated Systems Management application utilizes a centralized database,

so it was important to design a web-based application. ISM is used exclusively

by members of the US Coast Guard at various locations. Coast Guard employees

at various levels, including ship personnel, quartermasters, supply clerks and

harbor personnel, all have jobs to perform using the system.

ISM consists of several sub-systems, each of which performs separate but integrated

functions:

|

Engineering Baseline — Each boat that is built has an engineering baseline established.

Every component of the ship is documented as a "configuration item" and includes maintenance

information and associated parts schema.

|

|

Change Management — The change management system documents variances that are requested

during the boat building process. Workflow items are generated to take each change request

through the review and approval process, including procuring financing once the change is approved.

All approved change requests are retained since they are deviations from the predefined engineering

baseline.

|

|

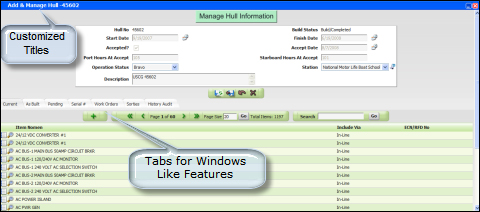

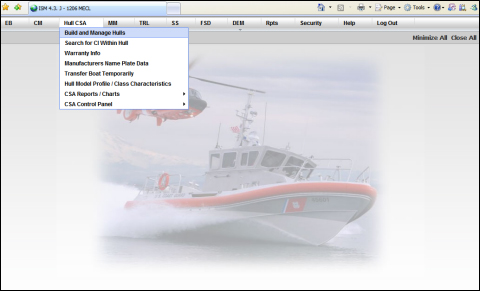

Hull Information — This sub-system documents the physical layout of a specific boat and

what is called the "Manufacturers Nameplate Data". Serial numbers for each component are recorded

and retained along with warranty information. Once the boat is launched, this sub-system also keeps

track of total days the boat is in service, as well as the number of "engine hours".

|

|

Maintenance — The maintenance sub-system keeps track of all scheduled maintenance (based on

boat usage), corrective actions (based on reported problems), and maintenance work orders that

are required to bring the boat up to engineering baseline specifications. Every work order must

be tracked from initiation to completion. This includes the actions taken at each step of the

process and the type and hours of workforce required for each step of the process, as well as

inventory items and tools required to perform each task.

|

|

Orders — The order sub-system keeps an inventory of supplies for maintenance. Based on the

boat's profile, the maintenance sub-system creates a list of supplies needed for a time period

relative to standard maintenance requirements. This function is especially important when a boat

is transferred from one station to another.

|

|

Technical Reference Library — This sub-system keeps track of all technical reference material

for every type of boat. The library can be searched by hull, by type of boat, by type of work order,

etc., to ensure the most current reference material is available.

|

|

Supply Store — The supply store sub-system tracks warranty claims against manufacturers after

a failure. The vendors' receiving process for fulfillment of supply orders is also tracked.

|

|

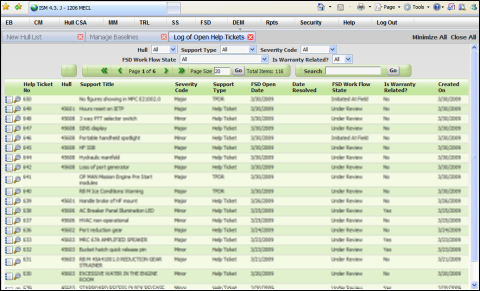

Field Support Desk — This sub-system creates help tickets for problem reporting and creates

the process flow for a help desk ticket.

|

|

Quality Control — The QC sub-system tracks all the distinct use cases within the ISM system and

allows each release of the software to be tested. Personnel can test each use case and document whether

the software version supports each requirement.

|

In addition to all of the above, the ISM application has integrated security,

supports multiple languages, can integrate with a report writer for ad hoc reports,

supports interaction with E-Commerce web sites for parts ordering, is Web Services

enabled with over 50 published web services, and provides for automated email notifications.

In order to use the real estate more effectively, we designed the Tab System which was security

enabled to only show users the options permitted based on their security role. Using Tabs also allowed

us to load only partial data to speed up the load times. For example, if a page has ten tabs, using

DHTML based tab system would have slowed the site, which usually loads the data for all the tabs.

The system is used differently by various Coast Guard personnel based on their

jobs and the current disposition of the boat they are working with. Different

sub-systems must be used based on what stage the boat is in: manufacturing, user

acceptance, normal usage, or undergoing major repairs.

|

Application size and scope |

The Integrated Systems Management application accesses one Microsoft SQL Server,

250 database tables with 150 database views, and around 2,000 web pages. The largest

database table is the Maintenance table, which contains about 1 million rows of code.

The application currently has around 100 users who support 13 boats. Once all

180 boats are in service, we anticipate the total number of users will increase

to around 1,000. Currently, the ISM application processes more than 500,000

transactions per month.

|

The project |

The project was implemented over a three-year period. The design was complex and

constantly being changed due to monthly Critical Design Reviews. When the application

was demonstrated during these review sessions, changes invariably arose, some of which

were so significant as to require a complete redesign and rewrite. This type of Agile

Development would not be possible without using Iron Speed Designer to build the

application.

The project team was six people at its largest, but was usually sized at four team

members. The application development took less than two years to complete.

|

Code extensions and customizations |

We had to write many code customizations for successful implementation of the application

— about 35,000 to 50,000 lines of code. As multiple developers were working on the application,

we tried to create Code Customization Templates. These templates were available through code

customizations to allow us to implement them in a consistent manner across the board.

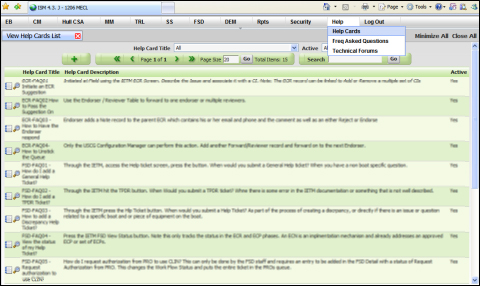

This is the main portal page a user would see after login. There are various sub-systems

that can be extended for their individual menus by hovering on their labels.

Code customizations included the following:

|

The framework was enhanced to provide a standardized user interface

|

|

Data access was streamlined for application performance

|

|

Change auditing had to be integrated into the application

|

|

Role based security and navigation was integrated along with language localization

|

Much of the customization was possible due to the architecture of Iron Speed Designer, which

allowed us to modify the Base Classes and Base Application Pages to streamline all the changes.

We did use third-party controls in the application, including extensive use of Telerik controls

and Crystal Reports.

The initial infrastructure build took approximately three months. After that, we used Code

Customization Templates to write all our routine code.

Integrated Help System is a hit as it allows the users to know more about the system with online

help available for each screen.

Help Cards and Frequently Asked Questions are maintained by the ISM

core group based on questions asked by the users during their operations.

|

Page layout customizations |

We made several page layout customizations to implement an application-specific design theme.

In order to allow easier navigation between systems, each major section starts a new subsection

like tabs in Internet Explorer. This allows the user to move from one page to the other rapidly.

The other option which users have reverted to in the past was to open multiple instances of the

application. However, it is cumbersome to work with multiple windows as compared to multiple tabs.

The data was not retrieved again if the user went back to a tab. In addition, the view state is

maintained and takes the user back to the same place they had been when working on a specific section.

|

Iron Speed Designer impact |

This application would have taken more than five years to develop without Iron Speed Designer

due to the constant changes in requirements and the need to recreate the application with

dramatic database changes. Another benefit to using Iron Speed Designer for development was

that each of the sub-systems was developed as a separate application for demonstration and

testing purposes and only integrated together at the end when all the functionality had been

approved. This would not have been possible using a standard development methodology.

We estimate that using Iron Speed Designer saved at least $1 million in project costs. In

addition the project would have required a much larger development team, as well as taking

more than five years to complete. The project would have been feasible without Iron Speed

Designer, but with significantly greater effort and cost.

|

Next steps |

We are currently using the framework developed during this application for more enterprise

class development. Much design and development went into the framework so that it could be

scaled to support 5,000 users with adequate performance in a distributed environment. The

lessons learned in how to architect the user interface, business logic and database access

layers are currently being used for high-performance large-scale application development.

This application will be scaled gradually to more than 1,000 users once all 180 boats have

been manufactured and brought into service. There are no plans to add additional web sites.

|

About the developer |

Master of Sciences — Northwestern University

MCSE+I, MCSD, MCDBA, MCT

Akesh is co-founder of Light Speed Solutions and ExecuTrain of Long Island.

He is passionate about technology and loves to share his knowledge with others. ExecuTrain of Long

Island is a corporate training company specializing in bringing real-world knowledge to the training

room. Light Speed Solutions is a professional consulting and software development company that focuses

on turning business vision into reality. Akesh Gupta has more than 14 years of experience in architecting,

designing and developing successful applications. Light Speed Solutions has become a one-stop solutions

center offering advanced, diversified expertise in all facets of development, with complementary expertise

in systems, reporting and accounting. Akesh holds a Master of Sciences degree from Northwestern University.

|

|

|

|

|

|

|

|